Top 11 quick wins for a sustainable lab

In this blog you will read all about sustainable improvements you can make in your laboratory. Will some effort and little investment, you can get some big results. We will release a quick win every Friday. Stay tuned for the top 11 quick wins.

11. Maximise transport

Smart procurement of goods not only prevents consumables and equipment from being left lying around in your warehouse or even products going past shelf-life, it also prevents you from having a truck at your warehouse door too often. So by optimizing your purchase, you will be able maximise transport and extend shelf-life, which will then result in minimizing CO2 emissions and reduce waste materials.

Combining transport of consumables & equipment is very efficient and sustainable, especially when transporting samples at extremely low temperatures. Also check whether inbound and outbound transport is fully optimised at your company.

10. Consider greener alternatives

For many appliances and consumables, alternatives can be found that are more sustainable. As a company, make conscious and well-considered choices when buying new equipment. Consider not only the price, but also what impact your purchase will have on the environment. For example, you can use labels with ink and glue to make your samples traceable. But you can also opt for AFYS3G’s laser equipment, which can laser anything you want on the surfaces of your consumables. With this, you will never have to use labels that might fall off your sample tube again. This often occurs in laboratories due to lower temperatures or the use of chemicals that dissolve the glue of labels. Then you no longer know what is stored in which tube and you can no longer use your valuable sample and consumables.

Note that not every sustainable alternative is also good for the quality of your research. In fact, a sustainable alternative may not meet your quality requirements. It is therefore always necessary to do a sample or demo request of all options on the market and see which one is most suitable for your working environment. Not sure which solution is best for your situation? Feel free to contact one of our specialists.

9. Reduce or preserve packaging

In many cases the packaging of consumables and equipment can be made a lot more sustainable. A good example is using cardboard packaging instead of plastic packaging. Cardboard packaging can be more easily recycled and in the unlikely event that cardboard does end up in nature, it decays completely and much more rapidly than plastics. With our pipette tips from Capp, you can choose which packaging is most suitable for you: cardboard packaging or the standard plastic packaging.

To make your own impact on the packaging industry, you can choose suppliers that use sustainable packaging. At NBS Scientific, we also go for the most ecological packaging. We reuse boxes for example, including those from other suppliers. We then also provide these boxes with a sticker (also made from recycled paper), so that you recognise that the box has been reused. Our tape is also extra strong, so we need to use less tape to safely package your equipment and consumables. Furthermore, we use paper padding, so that your products can be transported safely. In short, at NBS Scientific you can be sure that we send our shipments in the most ecological way possible.

8. Proper waste separation

An excellent quick-win is the thorough separation of different types of plastics. You can find which types of plastic have been used on the packaging or online. After plastic is recycled, it become less strong every time. Laboratory consumables are (often) made of one of the strongest plastic types. This guarantees not only that they are contamination-free, but also resistant to extremely low temperatures and various substances. From recycling these plastics, you can make products that are slightly lower on the plastic strength scale, such as toys. Plastic from toys can then be recycled into plastic packaging, for example to be used in the food industry. These plastic containers can then be recycled again into plastic waste bags, which are on the last life cycle of plastic. But combining different different grades of plastics will greatly degrade the overall quality of the end product. Thus, it is therefore necessary to separate plastic waste properly.

There are several initiatives that like to collect laboratory-grade plastic and equipment so that they can then be made into beautiful recycled products. For example, old (laboratory) refrigerators are being turned into toys. Look at different local initiatives to determine if your consumables or equipment can also be recycled.

7. Green energy

An obvious quick-win is investing in green energy. After all, the many devices in a laboratory consume a lot of energy. By switching to green energy, you ensure that your company is contributing to a better environment. Therefore, investing in a more sustainable source of power is a good ecological solution. Your company could consider installing solar panels to generate your own green energy. Check with your energy supplier about the possibilities.

Did you know that NBS Scientific runs entirely on green energy too? This even allows our colleagues’ electric cars to be charged with clean green energy. We also make a selection of our suppliers based on their sustainability policy, such as our supplier Capp. Not only do they have sustainable products such as the Capp Ecopipette, but their factory also runs entirely on green energy.

6. Switching off equipment

Switching off equipment that is not in use can save quite a bit of energy. This quick-win may seem somewhat obvious, but in a laboratory environment with a high throughput, this point is often overlooked. There are smart machines that switch off automatically when they are finished. For example, the SPL Guard Arizona can stop thawing your samples when it has reached the right temperature. Should you use equipment that does not have this feature, it is advisable to establish a protocol for this with your colleagues.

Note that even in standby mode, equipment still consumes power. First ask your supplier whether it is safe to switch these devices off completely, also because of possible updates. Make sure that the device should not be switched on again shortly afterwards, because turning it on temporarily uses more power. Use the following rules of thumb: a device that will not be used for more than 5 minutes can be put on standby. A device that is not going to be used for more than 15 minutes can be switched off completely.

5. Recycling consumables

Recycling your consumables is not always possible or profitable. However, there are situations where plastic consumables do not need to be cleaned or where a light cleaning can be sufficient to reuse them. Check with your colleagues where consumables can be reused to reduce plastic waste.

For example, NBS Scientific is working on NovaWash. In this programme, we clean sample racks/plates for a select group of customers. Check with your direct contact at NBS Scientific whether NovaWash is cost-effective for your organisation too.

4. Reduce consumables

Consumables, also known as disposables, are laboratory materials that are used only once. After one use, they are disposed of. As samples are often exposed to different substances and temperatures, these consumables often have to be made of high-quality plastic. By always using new consumables, you can guarantee that they are contamination-free. This creates a large mountain of plastic waste.

And excellent quick-win is to reduce these consumables if possible. There are innovations on the market with the aim of reducing the use of consumables. For example, think of equipment that can use larger volumes or low dead-volume, so you need to use fewer microplates, tubes and pipette tips. Dispendix’s new I.DOT is a perfect example where you need to use far fewer plastic consumables to achieve the same nanolitre volumes.

3. Sample traceability

A common cause of high freezer energy consumption is the continuous opening and closing of the freezer door. If the door is already open for more than 2 minutes, the freezer starts cooling quite extra and will drastically increase the number of kWh consumed by the freezer. Therefore, reducing the opening of the freezer is a must for a greener laboratory.

A lot of time is lost looking for the right samples in the laboratory freezer, which often is the main cause for leaving the door open unnecessarily. A good solution is to ensure optimal traceability of your samples. This can already be achieved by keeping a simple Microsoft Excel sheet. But with larger quantities of samples, this is not an efficient method. This is why Micronic’s sample storage racks are equipped with 1D barcodes. You can also choose bottom coded and hybrid tubes, these tubes have a 2D Data-Matrix code at the bottom. By using code scanners, you can read both types of codes: rack and tube codes. This allows you to easily keep track of where which sample is located and reduces the need to open your freezer.

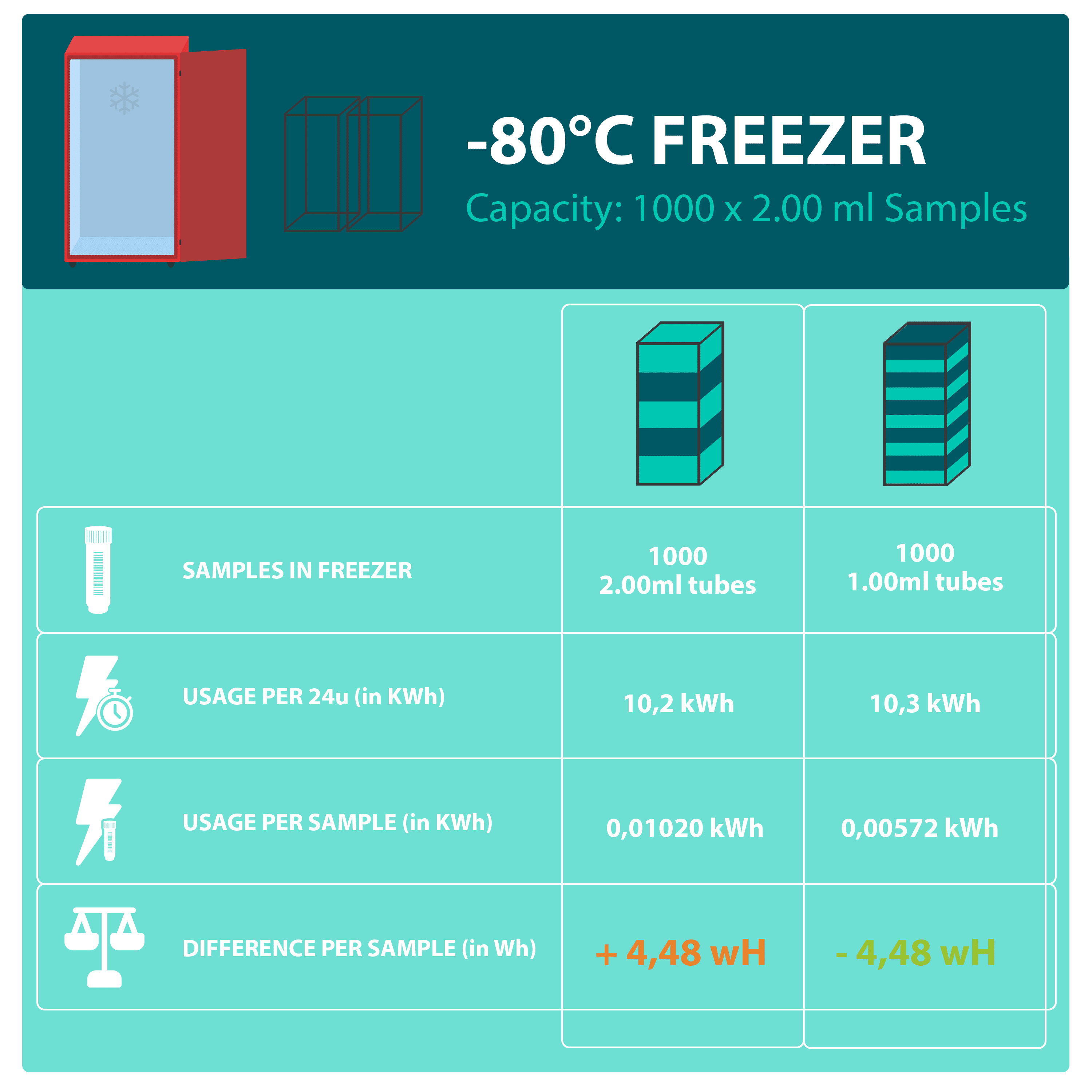

2. Optimise sample storage in racks

In many laboratories, there is a lot to be gained in terms of space planning within the sample storage racks. If you do not use all the space in your sample storage tubes, it is advisable to consider a smaller tube. Our sample storage tubes from Micronic are available in various heights and volumes. By using lower tubes, you can easily make use of lower racks as well. You can also use lower caps, for example there are special low profile screw caps in the market that can save up to 33% freezer space.

This becomes apparent in the example image below.

In short: by using lower tubes and lower caps, you can also use lower racks and thus fit more racks in your freezer(s).

Of course, you can combine the different techniques to create optimal sample storage. Want to calculate the optimal tube for your situation? Then use Micronic’s free sample tube configuration wizard.

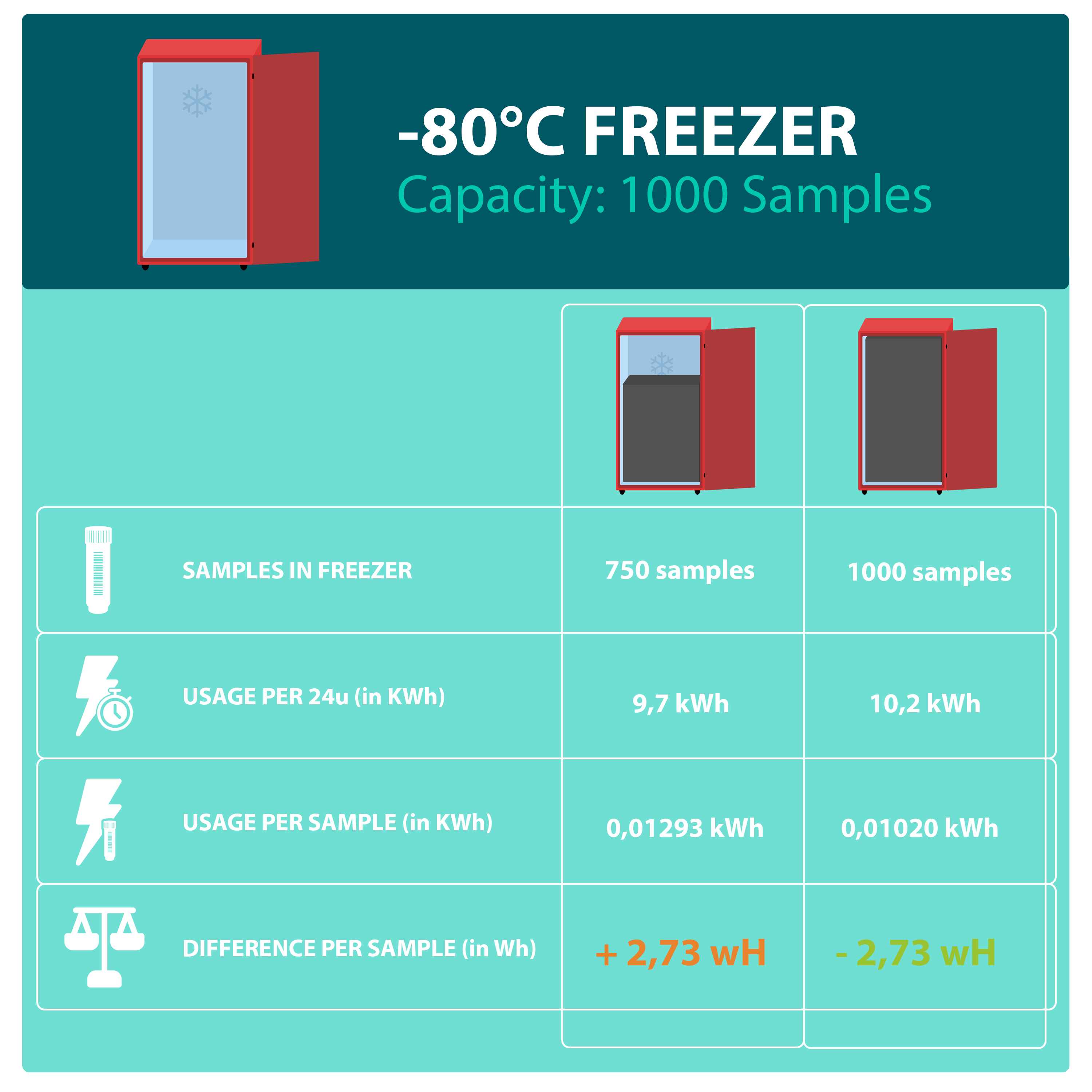

1. Optimise sample storage in freezers

We have known for a long time that freezers consume a lot of power; our home freezer uses electricity to cool itself 24 hours a day, all year round. To maintain its optimal temperature, it also consumes quite a few kWh. On average, a household freezer consumes 250 kWh per year. And household freezers do not even reach the temperatures of the -80°C freezers found in most laboratories and biobanks.

It is therefore important to optimise the space in your freezers. This means that its very important that every spot in the freezers is filled and that there are no or as few voids as possible. The less space in the freezers, the less power is consumed per stored sample.

As an example, let’s take a freezer with a total capacity of 1,000 sample tubes. If we do not fill it completely, let’s say only 75%, it will result in a freezer that is a lot less durable. Obviously, the freezer has to work a little bit harder to keep a fully filled freezer cool, but this outweighs the savings you can achieve per sample tube. So in the example below, the freezer saves you 2.73 Wh per sample tube more when fully filled.

To make sure you have an optimized space in your freezer, you can also take a look at the height of the sample storage racks. Micronic offer sample storage rack with different heights and also different covers depending on the size of the tube.

Thanks for reading all of our quick-wins! Stay up-to-date for future blogs. Follow us on Linked-In or Twitter (X) to know when we updated this blogs!